Restor Dent Endod.

2016 Nov;41(4):304-309. 10.5395/rde.2016.41.4.304.

Screw-in forces during instrumentation by various file systems

- Affiliations

-

- 1Department of Conservative Dentistry, School of Dentistry, Kyungpook National University, Daegu, Korea.

- 2Department of Conservative Dentistry, School of Dentistry, Dental Research Institute, Pusan National University, Yangsan, Korea. golddent@pusan.ac.kr

- KMID: 2356007

- DOI: http://doi.org/10.5395/rde.2016.41.4.304

Abstract

OBJECTIVES

The purpose of this study was to compare the maximum screw-in forces generated during the movement of various Nickel-Titanium (NiTi) file systems.

MATERIALS AND METHODS

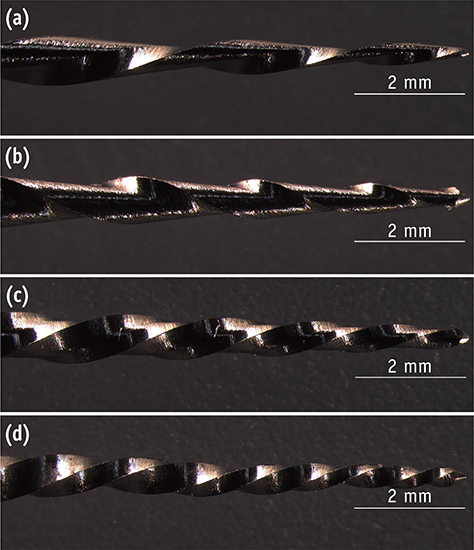

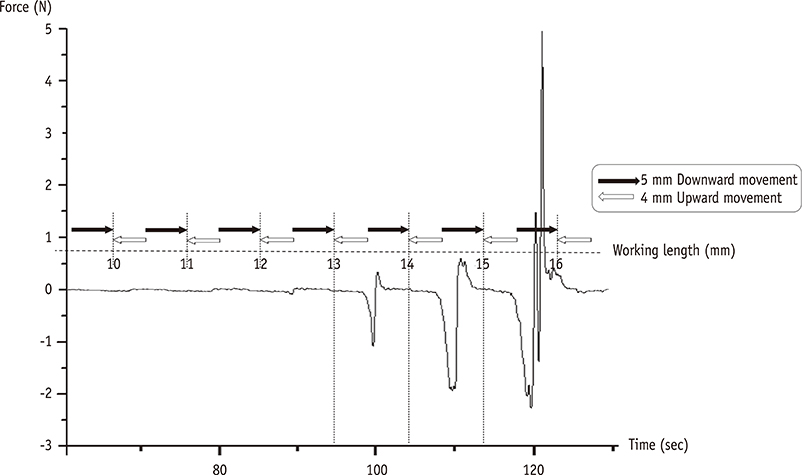

Forty simulated canals in resin blocks were randomly divided into 4 groups for the following instruments: Mtwo size 25/0.07 (MTW, VDW GmbH), Reciproc R25 (RPR, VDW GmbH), ProTaper Universal F2 (PTU, Dentsply Maillefer), and ProTaper Next X2 (PTN, Dentsply Maillefer, n = 10). All the artificial canals were prepared to obtain a standardized lumen by using ProTaper Universal F1. Screw-in forces were measured using a custom-made experimental device (AEndoS-k, DMJ system) during instrumentation with each NiTi file system using the designated movement. The rotation speed was set at 350 rpm with an automatic 4 mm pecking motion at a speed of 1 mm/sec. The pecking depth was increased by 1 mm for each pecking motion until the file reach the working length. Forces were recorded during file movement, and the maximum force was extracted from the data. Maximum screw-in forces were analyzed by one-way ANOVA and Tukey's post hoc comparison at a significance level of 95%.

RESULTS

Reciproc and ProTaper Universal files generated the highest maximum screw-in forces among all the instruments while M-two and ProTaper Next showed the lowest (p < 0.05).

CONCLUSIONS

Geometrical differences rather than shaping motion and alloys may affect the screw-in force during canal instrumentation. To reduce screw-in forces, the use of NiTi files with smaller cross-sectional area for higher flexibility is recommended.

MeSH Terms

Figure

Reference

-

1. Walia HM, Brantley WA, Gerstein H. An initial investigation of the bending and torsional properties of Nitinol root canal files. J Endod. 1988; 14:346–351.

Article2. Peters OA. Current challenges and concepts in the preparation of root canal systems: a review. J Endod. 2004; 30:559–567.

Article3. Sonntag D, Guntermann A, Kim SK, Stachniss V. Root canal shaping with manual stainless steel files and rotary Ni-Ti files performed by students. Int Endod J. 2003; 36:246–255.

Article4. Kim HC, Cheung GS, Lee CJ, Kim BM, Park JK, Kang SI. Comparison of forces generated during root canal shaping and residual stresses of three nickel-titanium rotary files by using a three-dimensional finite-element analysis. J Endod. 2008; 34:743–747.

Article5. Kim TO, Cheung GS, Lee JM, Kim BM, Hur B, Kim HC. Stress distribution of three NiTi rotary files under bending and torsional conditions using a mathematic analysis. Int Endod J. 2009; 42:14–21.

Article6. Kim HC, Kim HJ, Lee CJ, Kim BM, Park JK, Versluis A. Mechanical response of nickel-titanium instruments with different cross-sectional designs during shaping of simulated curved canals. Int Endod J. 2009; 42:593–602.

Article7. Zhang EW, Cheung GS, Zheng YF. Influence of cross-sectional design and dimension on mechanical behavior of nickel-titanium instruments under torsion and bending: a numerical analysis. J Endod. 2010; 36:1394–1398.

Article8. Versluis A, Kim HC, Lee W, Kim BM, Lee CJ. Flexural stiffness and stresses in nickel-titanium rotary files for various pitch and cross-sectional geometries. J Endod. 2012; 38:1399–1403.

Article9. Lam PP, Palamara JE, Messer HH. Fracture strength of tooth roots following canal preparation by hand and rotary instrumentation. J Endod. 2005; 31:529–532.

Article10. Kim HC, Lee MH, Yum J, Versluis A, Lee CJ, Kim BM. Potential relationship between design of nickel-titanium rotary instruments and vertical root fracture. J Endod. 2010; 36:1195–1199.

Article11. Ha JH, Park SS. Influence of glide path on the screw-in effect and torque of nickel-titanium rotary files in simulated resin root canals. Restor Dent Endod. 2012; 37:215–219.

Article12. Adorno CG, Yoshioka T, Suda H. Crack initiation on the apical root surface caused by three different nickel-titanium rotary files at different working lengths. J Endod. 2011; 37:522–525.

Article13. Diemer F, Calas P. Effect of pitch length on the behavior of rotary triple helix root canal instruments. J Endod. 2004; 30:716–718.

Article14. Park H. A comparison of Greater Taper files, ProFiles, and stainless steel files to shape curved root canals. Oral Surg Oral Med Oral Pathol Oral Radiol Endod. 2001; 91:715–718.

Article15. Sjogren U, Hagglund B, Sundqvist G, Wing K. Factors affecting the long-term results of endodontic treatment. J Endod. 1990; 16:498–504.

Article16. Dentsply maillefer: WAVEONE. updated 2016 Aug 08. Available from: http://www.dentsplymaillefer.com/product-category/glide-path-shaping/waveone.17. Schneider SW. A comparison of canal preparations in straight and curved root canals. Oral Surg Oral Med Oral Pathol. 1971; 32:271–275.

Article18. Kim JW, Ha JH, Cheung GS, Versluis A, Kwak SW, Kim HC. Safety of the factory preset rotation angle of reciprocating instruments. J Endod. 2014; 40:1671–1675.

Article19. Shen Y, Zhou HM, Zheng YF, Peng B, Haapasalo M. Current challenges and concepts of the thermomechanical treatment of nickel-titanium instruments. J Endod. 2013; 39:163–172.

Article20. Yum J, Cheung GS, Park JK, Hur B, Kim HC. Torsional strength and toughness of nickel-titanium rotary files. J Endod. 2011; 37:382–386.

Article21. Gambarini G, Plotino G, Grande NM, Al-Sudani D, De Luca M, Testarelli L. Mechanical properties of nickel-titanium rotary instruments produced with a new manufacturing technique. Int Endod J. 2011; 44:337–341.

Article22. Kim HC, Sung SY, Ha JH, Solomonov M, Lee JM, Lee CJ, Kim BM. Stress generation during self-adjusting file movement: minimally invasive instrumentation. J Endod. 2013; 39:1572–1575.

Article23. Ha JH, Cheung GS, Versluis A, Lee CJ, Kwak SW, Kim HC. 'Screw-in' tendency of rotary nickel-titanium files due to design geometry. Int Endod J. 2015; 48:666–672.

Article24. Elnaghy AM, Elsaka SE. Assessment of the mechanical properties of ProTaper Next nickel-titanium rotary files. J Endod. 2014; 40:1830–1834.

Article25. Gao Y, Gutmann JL, Wilkinson K, Maxwell R, Ammon D. Evaluation of the impact of raw materials on the fatigue and mechanical properties of ProFile Vortex rotary instruments. J Endod. 2012; 38:398–401.

Article26. Baek SH, Lee CJ, Versluis A, Kim BM, Lee W, Kim HC. Comparison of torsional stiffness of nickel-titanium rotary files with different geometric characteristics. J Endod. 2011; 37:1283–1286.

Article27. Lee MH, Versluis A, Kim BM, Lee CJ, Hur B, Kim HC. Correlation between experimental cyclic fatigue resistance and numerical stress analysis for nickel-titanium rotary files. J Endod. 2011; 37:1152–1157.

Article

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- Comparison of screw-in effect of three NiTi file systems used by undergraduates

- Selection of Nickel-Titanium Files according to the Clinical Procedure and Factors of File Fracture: A Narrative Review

- The Comparison between Hook and Screw Systems of Cotrel - Dubousset Instrumentation in Scoliosis

- Influence of glide path on the screw-in effect and torque of nickel-titanium rotary files in simulated resin root canals

- Follow-up Result of Transpedicular Screw Fixation in Lumbar Spinal Stenosis and Spondylolisthesis