Korean J Orthod.

2014 Jul;44(4):157-167. 10.4041/kjod.2014.44.4.157.

Comparison of frictional forces between aesthetic orthodontic coated wires and self-ligation brackets

- Affiliations

-

- 1Department of Orthodontics, College of Dentistry, Yonsei University, Seoul, Korea. yumichael@yuhs.ac

- KMID: 2273272

- DOI: http://doi.org/10.4041/kjod.2014.44.4.157

Abstract

OBJECTIVE

The purpose of this study was to evaluate the clinical efficacy of polymer- and rhodium-coated wires compared to uncoated wires by measuring the frictional forces using self-ligation brackets.

METHODS

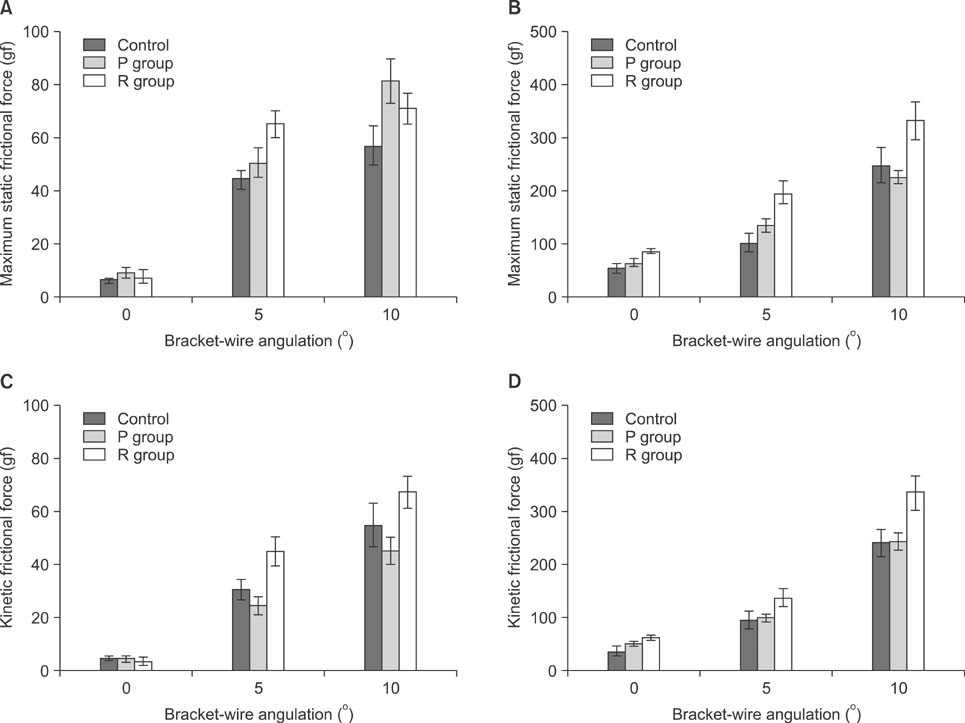

0.016-inch nickel titanium (NiTi) wires and 0.017 x 0.025-inch stainless steel (SS) wires were used, and the angulations between the brackets and wires were set to 0degrees, 5degrees, and 10degrees. Upper maxillary premolar brackets (Clippy-C(R)) with a 0.022-inch slot were selected for the study and a tensile test was performed with a crosshead speed of 5 mm/min. The maximum static frictional forces and kinetic frictional forces were recorded and compared.

RESULTS

The maximum static frictional forces and the kinetic frictional forces of coated wires were equal to or higher than those of the uncoated wires (p < 0.05). The maximum static frictional forces of rhodium-coated wires were significantly higher than those of polymer-coated wires when the angulations between the brackets and wires were set to (i) 5degrees in the 0.016-inch NiTi wires and (ii) all angulations in the 0.017 x 0.025-inch SS wires (p < 0.05). The kinetic frictional forces of rhodium-coated wires were higher than those of polymer-coated wires, except when the angulations were set to 0degrees in the 0.016-inch NiTi wires (p < 0.05).

CONCLUSIONS

Although the frictional forces of the coated wires with regards to aesthetics were equal to or greater than those of the uncoated wires, a study under similar conditions regarding the oral cavity is needed in order to establish the clinical implications.

Keyword

MeSH Terms

Figure

Cited by 1 articles

-

Resistance to sliding in orthodontics: misconception or method error? A systematic review and a proposal of a test protocol

Fabio Savoldi, Aggeliki Papoutsi, Simona Dianiskova, Domenico Dalessandri, Stefano Bonetti, James K. H. Tsoi, Jukka P. Matinlinna, Corrado Paganelli

Korean J Orthod. 2018;48(4):268-280. doi: 10.4041/kjod.2018.48.4.268.

Reference

-

1. Burrow SJ. Friction and resistance to sliding in orthodontics: a critical review. Am J Orthod Dentofacial Orthop. 2009; 135:442–447.

Article2. Kusy RP, Whitley JQ. Friction between different wire-bracket configurations and materials. Semin Orthod. 1997; 3:166–177.3. Neumann P, Bourauel C, Jäger A. Corrosion and permanent fracture resistance of coated and conventional orthodontic wires. J Mater Sci Mater Med. 2002; 13:141–147.4. Elayyan F, Silikas N, Bearn D. Ex vivo surface and mechanical properties of coated orthodontic archwires. Eur J Orthod. 2008; 30:661–667.

Article5. Elayyan F, Silikas N, Bearn D. Mechanical properties of coated superelastic archwires in conventional and self-ligating orthodontic brackets. Am J Orthod Dentofacial Orthop. 2010; 137:213–217.

Article6. Bandeira AM, dos Santos MP, Pulitini G, Elias CN, da Costa MF. Influence of thermal or chemical degradation on the frictional force of an experimental coated NiTi wire. Angle Orthod. 2011; 81:484–489.

Article7. Jang TH, Kim SC, Cho JH, Chae JM, Chang NY, Kang KH. The comparison of the frictional force by the type and angle of orthodontic bracket and the coated or non-coated feature of archwire. Korean J Orthod. 2011; 41:399–410.

Article8. Drescher D, Bourauel C, Schumacher HA. Frictional forces between bracket and arch wire. Am J Orthod Dentofacial Orthop. 1989; 96:397–404.

Article9. Frank CA, Nikolai RJ. A comparative study of frictional resistances between orthodontic bracket and arch wire. Am J Orthod. 1980; 78:593–609.

Article10. Kusy RP, Whitley JQ. Coefficients of friction for arch wires in stainless steel and polycrystalline alumina bracket slots. I. The dry state. Am J Orthod Dentofacial Orthop. 1990; 98:300–312.

Article11. Tselepis M, Brockhurst P, West VC. The dynamic frictional resistance between orthodontic brackets and arch wires. Am J Orthod Dentofacial Orthop. 1994; 106:131–138.

Article12. Iijima M, Muguruma T, Brantley W, Choe HC, Nakagaki S, Alapati SB, et al. Effect of coating on properties of esthetic orthodontic nickel-titanium wires. Angle Orthod. 2012; 82:319–325.

Article13. Kusy RP, Whitley JQ. Influence of archwire and bracket dimensions on sliding mechanics: derivations and determinations of the critical contact angles for binding. Eur J Orthod. 1999; 21:199–208.

Article

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- Evaluation of frictional forces between orthodontic brackets and archwires

- A comparative study of frictional resistances between orthodontic brackets and arch wire during sliding movement of teeth

- Frictional forces between orthodontic wire and bracket under artificial saliva

- The frictional resistance of tin ion-plated Co-Cr orthodontic wire

- A study on the changes of frictional force between bracket and orthodontic wire with time in artificial saliva