Korean J Orthod.

2011 Dec;41(6):423-430. 10.4041/kjod.2011.41.6.423.

Three-dimensional finite element analysis for determining the stress distribution after loading the bone surface with two-component mini-implants of varying length

- Affiliations

-

- 1Department of Prosthodontics, Yeouido St. Mary's Hospital, The Catholic University of Korea, Korea.

- 2Private Practice, Korea.

- 3Department of Orthodontics, Yeouido St. Mary's Hospital, The Catholic University of Korea, Korea.

- 4Department of Orthodontics, School of Dentistry, Kyung Hee University, Korea.

- 5Department of Orthodontics, School of Clinical Dental Scinece, Ajou University, Korea.

- 6Department of Orofacial Science, University of California in San Francisco, USA.

- 7Department of Orthodontics, St. Vincent Hospital, The Catholic University of Korea, Korea. seonghh@hotmail.com

- KMID: 2273190

- DOI: http://doi.org/10.4041/kjod.2011.41.6.423

Abstract

OBJECTIVE

To evaluate the extent and aspect of stress to the cortical bone after application of a lateral force to a two-component orthodontic mini-implant (OMI, mini-implant) by using three-dimensional finite element analysis (FEA).

METHODS

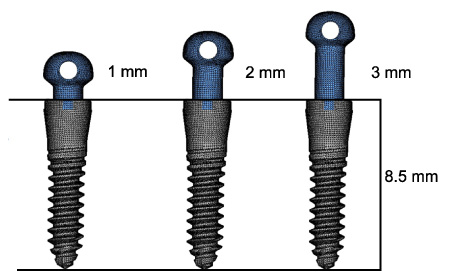

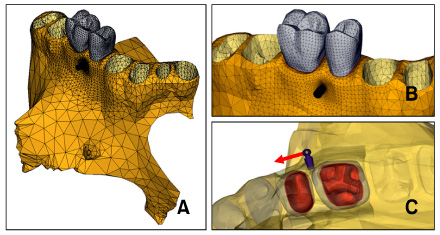

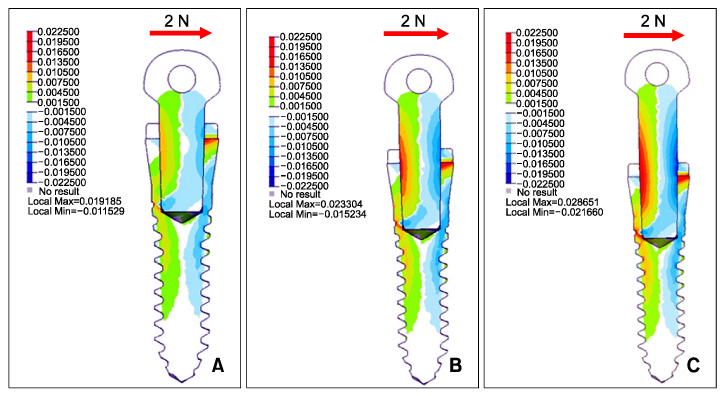

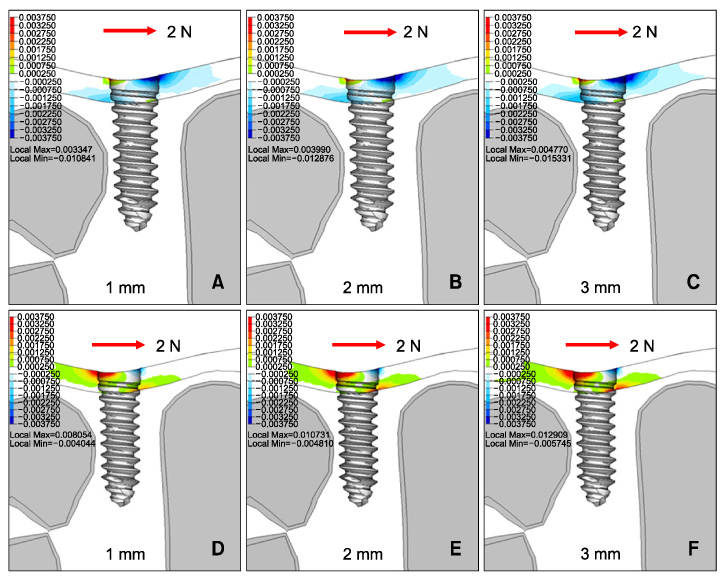

The 3D-finite element models consisted of the maxilla, maxillary first molars, second premolars, and OMIs. The screw part of the OMI had a diameter of 1.8 mm and length of 8.5 mm and was placed between the roots of the upper second premolar and the first molar. The cortical bone thickness was set to 1 mm. The head part of the OMI was available in 3 sizes: 1 mm, 2 mm, and 3 mm. After a 2 N lateral force was applied to the center of the head part, the stress distribution and magnitude were analyzed using FEA.

RESULTS

When the head part of the OMI was friction fitted (tapped into place) into the inserted screw part, the stress was uniformly distributed over the surface where the head part was inserted. The extent of the minimum principal stress suggested that the length of the head part was proportionate with the amount of stress to the cortical bone; the stress varied between 10.84 and 15.33 MPa.

CONCLUSIONS

These results suggest that the stress level at the cortical bone around the OMI does not have a detrimental influence on physiologic bone remodeling.

Figure

Reference

-

1. Byloff FK, Kärcher H, Clar E, Stoff F. An implant to eliminate anchorage loss during molar distalization: a case report involving the Graz implant-supported pendulum. Int J Adult Orthodon Orthognath Surg. 2000. 15:129–137.2. Creekmore TD, Eklund MK. The possibility of skeletal anchorage. J Clin Orthod. 1983. 17:266–269.3. Deguchi T, Takano-Yamamoto T, Kanomi R, Hartsfield JK Jr, Roberts WE, Garetto LP. The use of small titanium screws for orthodontic anchorage. J Dent Res. 2003. 82:377–381.

Article4. Kanomi R. Mini-implant for orthodontic anchorage. J Clin Orthod. 1997. 31:763–767.5. Costa A, Raffainl M, Melsen B. Miniscrews as orthodontic anchorage: a preliminary report. Int J Adult Orthodon Orthognath Surg. 1998. 13:201–209.6. Park HS, Lee SK, Kwon OW. Group distal movement of teeth using microscrew implant anchorage. Angle Orthod. 2005. 75:602–609.7. Park SH, Kim SH, Ryu JH, Kang YG, Chung KR, Kook YA. Bone-implant contact and mobility of surface-treated orthodontic micro-implants in dogs. Korean J Orthod. 2008. 38:416–426.

Article8. Chae JM, Chang NY, Cho JH, Kang KH, Kim SC. Treatment of skeletal Class II adult patient with vertical and transverse problems caused by nasal airway obstruction using microimplant anchorage. Korean J Orthod. 2009. 39:257–272.

Article9. Moon CH, Lee JS, Lee HS, Choi JH. Non-surgical treatment and retention of open bite in adult patients with orthodontic mini-implants. Korean J Orthod. 2009. 39:402–419.

Article10. Kim SH, Kook YA, Lee W, Kim I, Chung KR. Two-component mini-implant as an efficient tool for orthognathic patients. Am J Orthod Dentofacial Orthop. 2009. 135:110–117.

Article11. Kim SH, Cho JH, Chung KR, Kook YA, Nelson G. Removal torque values of surface-treated mini-implants after loading. Am J Orthod Dentofacial Orthop. 2008. 134:36–43.

Article12. Kim SH, Lee SJ, Cho IS, Kim SK, Kim TW. Rotational resistance of surface-treated mini-implants. Angle Orthod. 2009. 79:899–907.

Article13. Jeong DM, Choi B, Choo H, Kim JH, Chung KR, Kim SH. Novel application of the 2-piece orthodontic mini-implant for temporary crown restoration after orthodontic treatment. Am J Orthod Dentofacial Orthop. 2011. 140:569–579.

Article14. Ding X, Liao SH, Zhu XH, Zhang XH, Zhang L. Effect of diameter and length on stress distribution of the alveolar crest around immediate loading implants. Clin Implant Dent Relat Res. 2009. 11:279–287.

Article15. Ding X, Zhu XH, Liao SH, Zhang XH, Chen H. Implant-bone interface stress distribution in immediately loaded implants of different diameters: a three-dimensional finite element analysis. J Prosthodont. 2009. 18:393–402.

Article16. Haack JE, Sakaguchi RL, Sun T, Coffey JP. Elongation and preload stress in dental implant abutment screws. Int J Oral Maxillofac Implants. 1995. 10:529–536.17. Kinni ME, Hokama SN, Caputo AA. Force transfer by osseointegration implant devices. Int J Oral Maxillofac Implants. 1987. 2:11–14.18. Rieger MR, Mayberry M, Brose MO. Finite element analysis of six endosseous implants. J Prosthet Dent. 1990. 63:671–676.

Article19. Sakaguchi RL, Borgersen SE. Nonlinear contact analysis of preload in dental implant screws. Int J Oral Maxillofac Implants. 1995. 10:295–302.20. Motoyoshi M, Inaba M, Ono A, Ueno S, Shimizu N. The effect of cortical bone thickness on the stability of orthodontic mini-implants and on the stress distribution in surrounding bone. Int J Oral Maxillofac Surg. 2009. 38:13–18.

Article21. Park JS, Yu WJ, Kyung HM, Kwon OW. Finite element analysis of cortical bone strain induced by self-drilling placement of orthodontic microimplant. Korean J Orthod. 2009. 39:203–212.

Article22. Tanne K, Sakuda M, Burstone CJ. Three-dimensional finite element analysis for stress in the periodontal tissue by orthodontic forces. Am J Orthod Dentofacial Orthop. 1987. 92:499–505.

Article23. Poppe M, Bourauel C, Jäger A. Determination of the elasticity parameters of the human periodontal ligament and the location of the center of resistance of single-rooted teeth a study of autopsy specimens and their conversion into finite element models. J Orofac Orthop. 2002. 63:358–370.

Article24. Sertgöz A, Güvener S. Finite element analysis of the effect of cantilever and implant length on stress distribution in an implant-supported fixed prosthesis. J Prosthet Dent. 1996. 76:165–169.

Article25. Skalak R. Biomechanical considerations in osseointegrated prostheses. J Prosthet Dent. 1983. 49:843–848.

Article26. Merz BR, Hunenbart S, Belser UC. Mechanics of the implant-abutment connection: an 8-degree taper compared to a butt joint connection. Int J Oral Maxillofac Implants. 2000. 15:519–526.27. Mazor Z, Steigmann M, Leshem R, Peleg M. Mini-implants to reconstruct missing teeth in severe ridge deficiency and small interdental space: a 5-year case series. Implant Dent. 2004. 13:336–341.

Article28. Baurmash H. Bonded arch bars in oral and maxillofacial surgery. An update. Oral Surg Oral Med Oral Pathol. 1993. 76:553–556.29. Seo W, Kim SH, Chung KR, Nelson G. A pilot study of the osseointegration potential of a surface-treated mini-implant: bone contact of implants retrieved from patients. World J Orthod. 2009. 10:202–210.30. Chung KR, Choo H, Lee JH, Kim SH. Atypical orthodontic extraction pattern managed by differential en-masse retraction against a temporary skeletal anchorage device in the treatment of bimaxillary protrusion. Am J Orthod Dentofacial Orthop. 2011. 140:423–432.

Article31. Shatkin TE, Shatkin S, Oppenheimer BD, Oppenheimer AJ. Mini dental implants for long-term fixed and removable prosthetics: a retrospective analysis of 2514 implants placed over a five-year period. Compend Contin Educ Dent. 2007. 28:92–99.32. Frost HM. Bone's mechanostat: a 2003 update. Anat Rec A Discov Mol Cell Evol Biol. 2003. 275:1081–1101.

Article33. Sugiura T, Horiuchi K, Sugimura M, Tsutsumi S. Evaluation of threshold stress for bone resorption around screws based on in vivo strain measurement of miniplate. J Musculoskelet Neuronal Interact. 2000. 1:165–170.

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- Three-dimensional finite element analysis for stress distribution on the diameter of orthodontic mini-implants and insertion angle to the bone surface

- Contact non-linear finite element model analysis of initial stability of mini implant

- Finite element stress analysis of maxillary two implants-retained overdenture according go position of implant fixtures

- Three dimensional finite element method for stress distribution on the length and diameter of orthodontic miniscrew and cortical bone thickness

- Three-dimensional finite element analysis according to the insertion depth of an immediately loaded implant in the anterior maxilla