J Korean Acad Prosthodont.

2016 Apr;54(2):93-102. 10.4047/jkap.2016.54.2.93.

Comparison of marginal and internal fit of zirconia abutments with titanium abutments in internal hexagonal implants

- Affiliations

-

- 1Department of Prosthodontics, College of Dentistry, Wonkwang University, Iksan, Republic of Korea. hwcho@wku.ac.kr

- KMID: 2162384

- DOI: http://doi.org/10.4047/jkap.2016.54.2.93

Abstract

- PURPOSE

The aim of this study was to evaluate the fit accuracy of two zirconia and titanium abutments in internal hexagonal implants.

MATERIALS AND METHODS

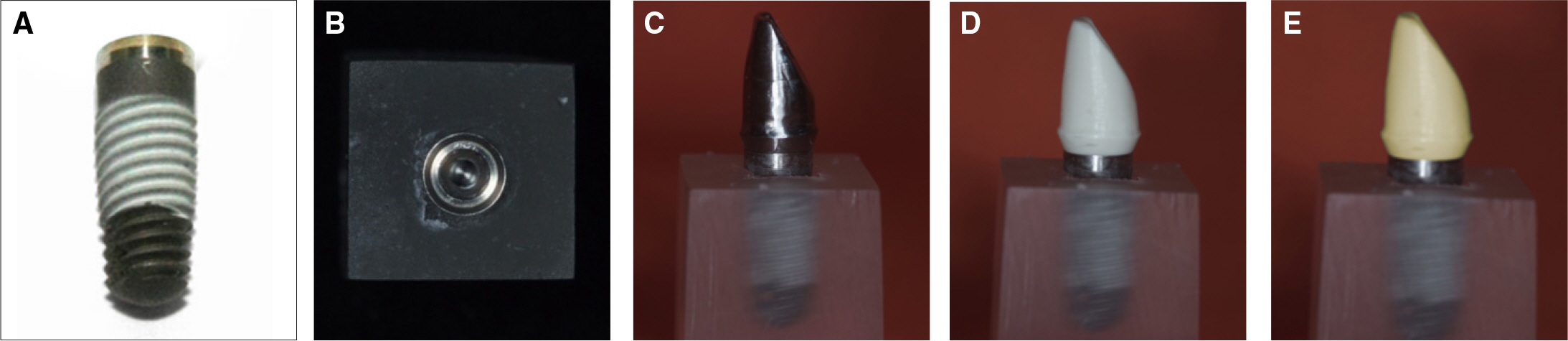

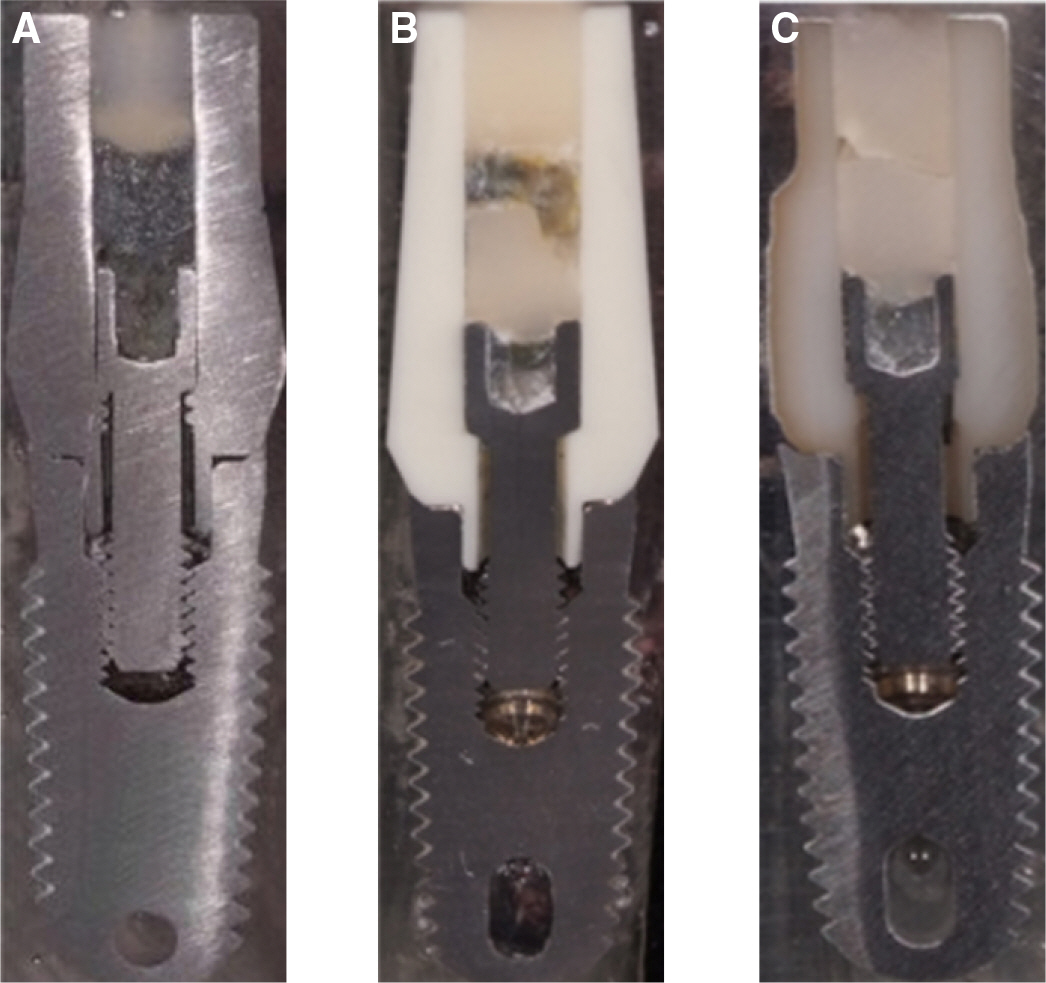

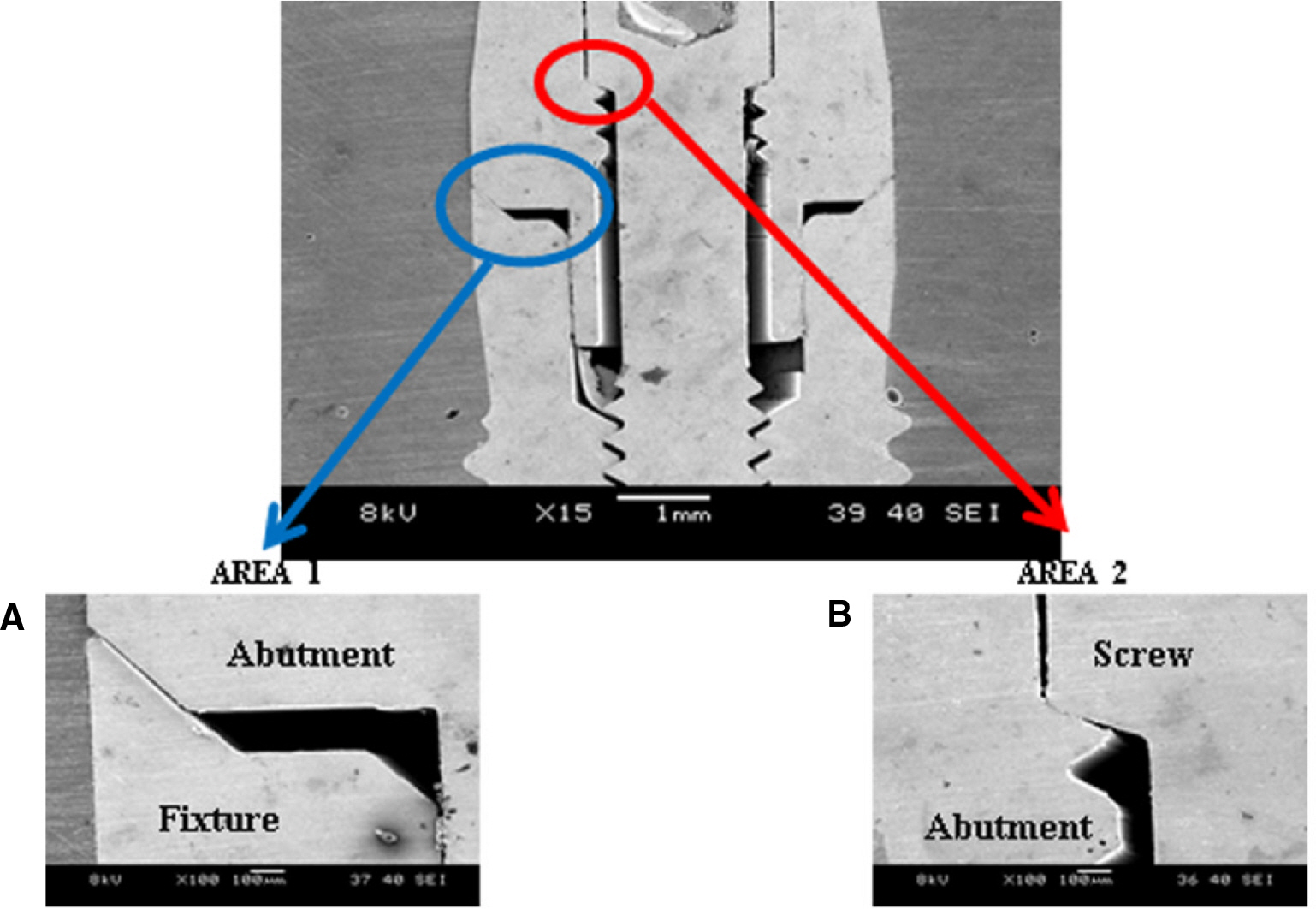

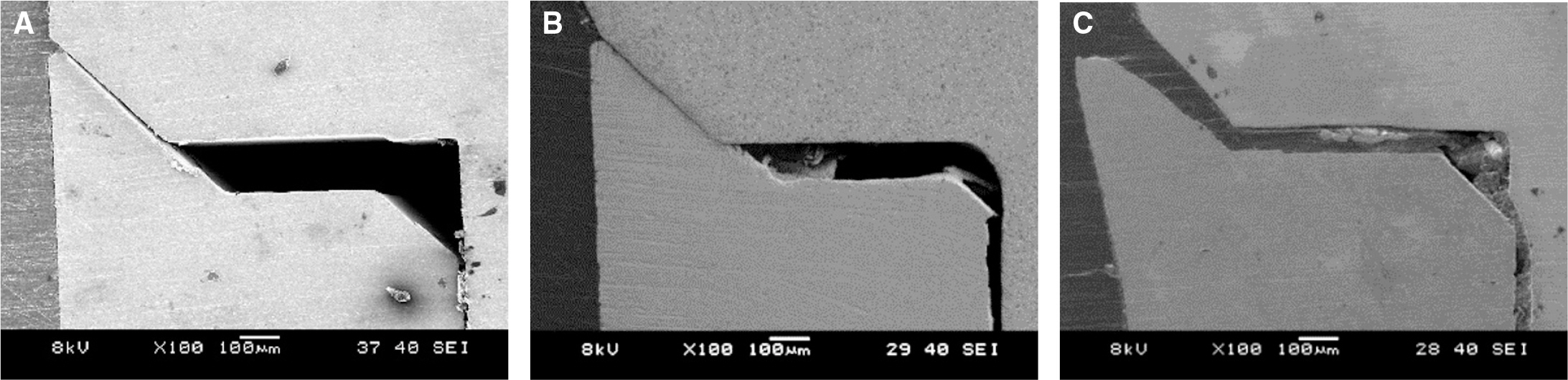

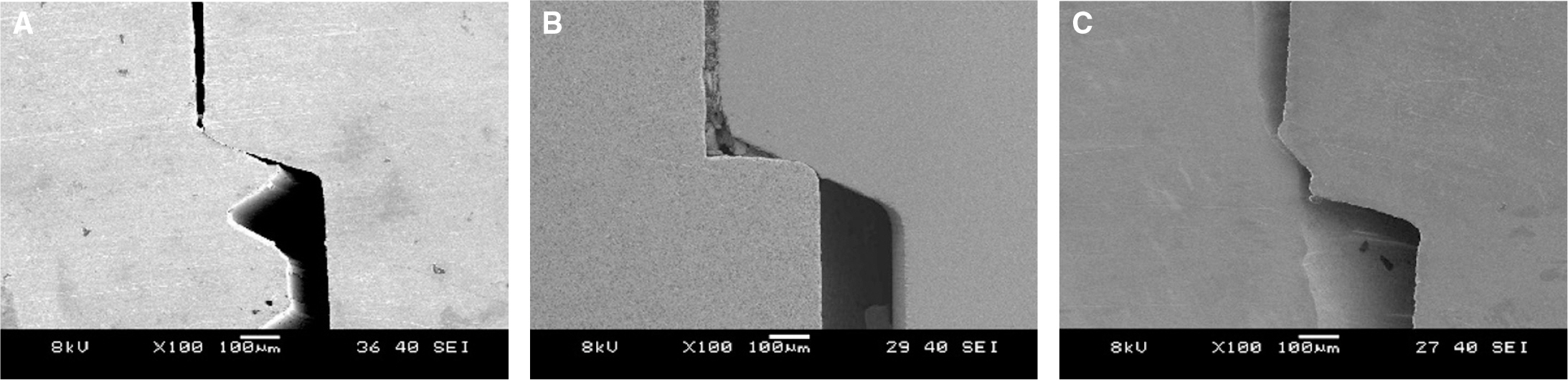

One titanium abutment and two zirconia abutments were tested in internal hexagonal implants (TSV, Zimmer). Prefabricated zirconia abutments (ZirAce, Acucera) and customized zirconia abutments milled by the Zirkonzahn system (Zirkonzahn Max, Zirkonzahn) were selected and prefabricated titanium abutments (Hex-Lock, Zimmer) were used as a control. Eight abutments per group were connected to implants with 30 Ncm torque. The marginal gaps at abutment-implant interface, the internal gaps at internal hex, vertical and horizontal gaps between screws and screw seats in abutments were measured after sectioning the embedded specimens using a scanning electron microscope. Data analysis included one-way analysis of variance and the Scheffe test (n=16, α=0.05).

RESULTS

The mean marginal gap of customized zirconia abutment was higher than those of two prefabricated zirconia and titanium abutments. The internal gaps at internal hex showed no significant differences between customized and prefabricated abutments and were higher than those of prefabricated titanium abutments. The mean vertical and horizontal gaps at screw in prefabricated zirconia abutment were higher than those of prefabricated titanium abutment. In the case of customized zirconia abutment, the mean horizontal gap at screw was higher than those of both the prefabricated zirconia and the titanium abutment but the mean vertical gap was not even measureable. The screw seats were clearly formed but did not match with abutment screws in prefabricated zirconia abutments. They were not, however, precisely formed in the case of customized zirconia abutments.

CONCLUSION

Within the limitations of this study, the prefabricated titanium abutments showed better fit than the zirconia abutments, regardless of customized or prefabricated. Also, the customized zirconia abutments showed significantly higher marginal gaps and the fit was less accurate between screws and screw seats than the prefabricated abutments, titanium and zirconia.

Keyword

MeSH Terms

Figure

Reference

-

1.Andersson B., Odman P., Lindvall AM., Brånemark PI. Cemented single crowns on osseointegrated implants after 5 years: results from a prospective study on CeraOne. Int J Prosthodont. 1998. 11:212–8.2.Yildirim M., Edelhoff D., Hanisch O., Spiekermann H. Ceramic abutments—a new era in achieving optimal esthetics in implant dentistry. Int J Periodontics Restorative Dent. 2000. 20:81–91.3.Piconi C., Maccauro G. Zirconia as a ceramic biomaterial. Biomaterials. 1999. 20:1–25.

Article4.Heydecke G., Butz F., Hussein A., Strub JR. Fracture strength after dynamic loading of endodontically treated teeth restored with different post-and-core systems. J Prosthet Dent. 2002. 87:438–45.

Article5.Jeong HC. Fracture strength of zirconia monolithic crowns. J Korean Acad Prosthodont. 2006. 44:157–64.6.Shin ES., Lee YS., Park WH. Comparative study in fracture strength of zirconia cores fabricated with three different CAD/CAM systems. J Korean Acad Prosthodont. 2008. 46:22–30.7.Kwon YJ., Lee YS., Park WH. Comparative study in marginal adaptation of zirconia cores fabricated with three different CAD/CAM systems. J Korean Acad Prosthodont. 2008. 46:12–21.8.Sicilia A., Quirynen M., Fontolliet A., Francisco H., Friedman A., Linkevicius T., Lutz R., Meijer HJ., Rompen E., Rotundo R., Schwarz F., Simion M., Teughels W., Wennerberg A., Zuhr O. Longterm stability of peri-implant tissues after bone or soft tissue augmentation. Effect of zirconia or titanium abutments on peri-implant soft tissues. Summary and consensus statements. The 4th EAO Consensus Conference 2015. Clin Oral Implants Res. 2015. 26:148–52.

Article9.Linkevicius T., Vaitelis J. The effect of zirconia or titanium as abutment material on soft peri-implant tissues: a systematic review and meta-analysis. Clin Oral Implants Res. 2015. 26:139–47.

Article10.Canullo L. Clinical outcome study of customized zirconia abutments for single-implant restorations. Int J Prosthodont. 2007. 20:489–93.11.Park JI., Lee Y., Lee JH., Kim YL., Bae JM., Cho HW. Comparison of fracture resistance and fit accuracy of customized zirconia abutments with prefabricated zirconia abutments in internal hexagonal implants. Clin Implant Dent Relat Res. 2013. 15:769–78.

Article12.Zembic A., Philipp AO., Hämmerle CH., Wohlwend A., Sailer I. Eleven-Year Follow-Up of a Prospective Study of Zirconia Implant Abutments Supporting Single All-Ceramic Crowns in Anterior and Premolar Regions. Clin Implant Dent Relat Res. 2015. 17:e417–26.

Article13.Jansen VK., Conrads G., Richter EJ. Microbial leakage and marginal fit of the implant-abutment interface. Int J Oral Maxillofac Implants. 1997. 12:527–40.14.Gomes AL., Montero J. Zirconia implant abutments: a review. Med Oral Patol Oral Cir Bucal. 2011. 16:e50–5.

Article15.Contrepois M., Soenen A., Bartala M., Laviole O. Marginal adaptation of ceramic crowns: a systematic review. J Prosthet Dent. 2013. 110:447–454.

Article16.Byrne D., Houston F., Cleary R., Claffey N. The fit of cast and prema-chined implant abutments. J Prosthet Dent. 1998. 80:184–92.

Article17.Yüzügüllü B., Avci M. The implant-abutment interface of alumina and zirconia abutments. Clin Implant Dent Relat Res. 2008. 10:113–21.

Article18.Kanno T., Milleding P., Wennerberg A. Topography, microhardness, and precision of fit on ready-made zirconia abutment before/after sintering process. Clin Implant Dent Relat Res. 2007. 9:156–65.

Article19.Hjerppe J., Lassila LV., Rakkolainen T., Narhi T., Vallittu PK. Load-bearing capacity of custom-made versus prefabricated commercially available zirconia abutments. Int J Oral Maxillofac Implants. 2011. 26:132–8.20.Baldassarri M., Hjerppe J., Romeo D., Fickl S., Thompson VP., Stappert CF. Marginal accuracy of three implant-ceramic abutment configurations. Int J Oral Maxillofac Implants. 2012. 27:537–43.21.Ribeiro IL., Campos F., Sousa RS., Alves ML., Rodrigues DM., Souza RO., Bottino MA. Marginal and internal discrepancies of zirconia copings: effects of milling system and finish line design. Indian J Dent Res. 2015. 26:15–20.

Article22.Alikhasi M., Monzavi A., Bassir SH., Naini RB., Khosronedjad N., Keshavarz S. A comparison of precision of fit, rotational freedom, and torque loss with copy-milled zirconia and prefabricated titanium abutments. Int J Oral Maxillofac Implants. 2013. 28:996–1002.

Article23.Gilbert AB., Yilmaz B., Seidt JD., McGlumphy EA., Clelland NL., Chien HH. Three-Dimensional Displacement of Nine Different Abutments for an Implant with an Internal Hexagon Platform. Int J Oral Maxillofac Implants. 2015. 30:781–8.

Article24.Hoyer SA., Stanford CM., Buranadham S., Fridrich T., Wagner J., Gratton D. Dynamic fatigue properties of the dental implant-abutment interface: joint opening in wide-diameter versus standard-diameter hex-type implants. J Prosthet Dent. 2001. 85:599–607.

Article25.Sui X., Wei H., Wang D., Han Y., Deng J., Wang Y., Wang J., Yang J. Experimental research on the relationship between fit accuracy and fracture resistance of zirconia abutments. J Dent. 2014. 42:1353–9.

Article26.Smith NA., Turkyilmaz I. Evaluation of the sealing capability of implants to titanium and zirconia abutments against Porphyromonas gingivalis, Prevotella intermedia, and Fusobacterium nucleatum under different screw torque values. J Prosthet Dent. 2014. 112:561–7.

Article27.Abdelhamed MI., Galley JD., Bailey MT., Johnston WM., Holloway J., McGlumphy E., Leblebicioglu B. A Comparison of Zirconia and Titanium Abutments for Microleakage. Clin Implant Dent Relat Res. 2015. 17:e643–51.

Article28.Park SD., Lee Y., Kim YL., Yu SH., Bae JM., Cho HW. Microleakage of different sealing materials in access holes of internal connection implant systems. J Prosthet Dent. 2012. 108:173–80.

Article29.Kang DR., Shim JS., Moon HS., Lee KW. Marginal fidelity of zirconia core using MAD/MAM system. J Korean Acad Prosthodont. 2010. 48:1–7.

Article30.Lee JH., Kim DG., Park CJ., Cho LR. Axial displacements in external and internal implant-abutment connection. Clin Oral Implants Res. 2014. 25:e83–9.

Article

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- Effect of casting procedure on screw loosening of UCLA abutment in two implant-abutment connection systems

- Comparison of fit accuracy and torque maintenance of zirconia and titanium abutments for internal tri-channel and external-hex implant connections

- Sealing capability and marginal fit of titanium versus zirconia abutments with different connection designs

- Effect of coloring treatment of translucent zirconia on the masking ability of metal abutment

- Effects of abutment angulation and type of connection on the fracture strength of zirconia abutments