J Yeungnam Med Sci.

2024 Apr;41(2):80-85. 10.12701/jyms.2023.00934.

Marginal fit of three different nanocomposite inlays fabricated with computer-aided design/computer-aided manufacturing (CAD/CAM) technology: a comparative study

- Affiliations

-

- 1Department of Dentistry and Prosthodontics, Catholic University of Daegu School of Medicine, Daegu, Korea

- 2Department of Dental Laboratory Science, College of Health Sciences, Catholic University of Pusan, Busan, Korea

- KMID: 2554768

- DOI: http://doi.org/10.12701/jyms.2023.00934

Abstract

- Background

This study aimed to compare and evaluate the marginal fit of nanocomposite computer-aided design/computer-aided manufacturing (CAD/CAM) inlays. Three types of nanocomposite CAD/CAM blocks (HASEM, VITA Enamic, and Lava Ultimate) were used as materials.

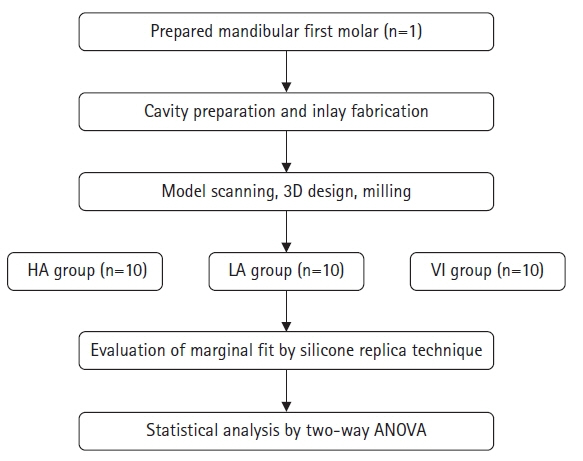

Methods

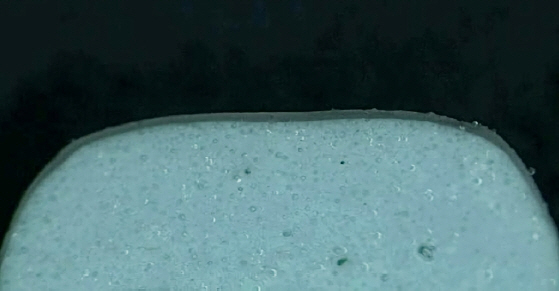

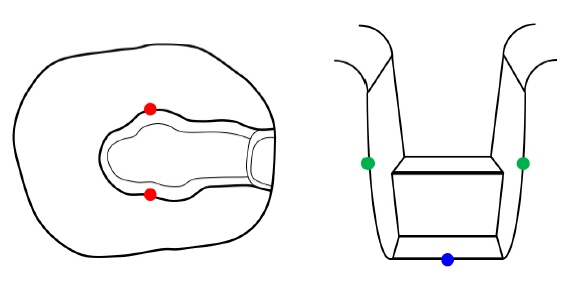

Class II disto-occlusal inlay restorations were prepared on a typodont mandibular right first molar using diamond rotary instruments. The inlays were fabricated using CAD/CAM technology and evaluated using the silicone replica technique to measure marginal gaps at five locations on each inlay. The data were analyzed by two-way analysis of variance and Tukey post hoc tests ( α=0.05).

Results

There were no significant differences in the marginal gaps based on the type of nanocomposite CAD/CAM inlay used (p=0.209). However, there was a significant difference in the marginal gaps between the measurement regions. The gingival region consistently exhibited a larger marginal gap than the axial and occlusal regions (p<0.001).

Conclusion

Within the limitations of this in vitro study, the measurement location significantly influenced the marginal fit of class II disto-occlusal inlay restorations. However, there were no significant differences in the marginal gaps among the different types of CAD/CAM blocks. Furthermore, the overall mean marginal fits of the class II disto-occlusal inlay restorations made with the three types of nanocomposite CAD/CAM blocks were within the clinically acceptable range.

Figure

Reference

-

References

1. Qian K, Yang X, Feng H, Liu Y. Marginal adaptation of different hybrid ceramic inlays after thermal cycling. Adv Appl Ceram. 2020; 119:1–7.

Article2. Esquivel-Upshaw JF, Anusavice KJ, Yang MC, Lee RB. Fracture resistance of all-ceramic and metal-ceramic inlays. Int J Prosthodont. 2001; 14:109–14.3. Nakamura T, Imanishi A, Kashima H, Ohyama T, Ishigaki S. Stress analysis of metal-free polymer crowns using the three-dimensional finite element method. Int J Prosthodont. 2001; 14:401–5.4. Homsy FR, Özcan M, Khoury M, Majzoub ZA. Comparison of fit accuracy of pressed lithium disilicate inlays fabricated from wax or resin patterns with conventional and CAD-CAM technologies. J Prosthet Dent. 2018; 120:530–6.

Article5. Homsy FR, Özcan M, Khoury M, Majzoub ZA. Marginal and internal fit of pressed lithium disilicate inlays fabricated with milling, 3D printing, and conventional technologies. J Prosthet Dent. 2018; 119:783–90.

Article6. Lauvahutanon S, Takahashi H, Shiozawa M, Iwasaki N, Asakawa Y, Oki M, et al. Mechanical properties of composite resin blocks for CAD/CAM. Dent Mater J. 2014; 33:705–10.

Article7. Paolone G, Mandurino M, De Palma F, Mazzitelli C, Scotti N, Breschi L, et al. Color stability of polymer-based composite CAD/CAM blocks: a systematic review. Polymers (Basel). 2023; 15:464.

Article8. Sidhom M, Zaghloul H, Mosleh IE, Eldwakhly E. Effect of different CAD/CAM milling and 3D printing digital fabrication techniques on the accuracy of PMMA working models and vertical marginal fit of PMMA provisional dental prosthesis: an in vitro study. Polymers (Basel). 2022; 14:1285.

Article9. Jeong YG, Lee WS, Lee KB. Accuracy evaluation of dental models manufactured by CAD/CAM milling method and 3D printing method. J Adv Prosthodont. 2018; 10:245–51.

Article10. Sorensen JA. A standardized method for determination of crown margin fidelity. J Prosthet Dent. 1990; 64:18–24.

Article11. Park JY, Bae SY, Lee JJ, Kim JH, Kim HY, Kim WC. Evaluation of the marginal and internal gaps of three different dental prostheses: comparison of the silicone replica technique and three-dimensional superimposition analysis. J Adv Prosthodont. 2017; 9:159–69.

Article12. Nawafleh NA, Mack F, Evans J, Mackay J, Hatamleh MM. Accuracy and reliability of methods to measure marginal adaptation of crowns and FDPs: a literature review. J Prosthodont. 2013; 22:419–28.

Article13. Kim KB, Kim JH, Kim WC, Kim HY, Kim JH. Evaluation of the marginal and internal gap of metal-ceramic crown fabricated with a selective laser sintering technology: two- and three-dimensional replica techniques. J Adv Prosthodont. 2013; 5:179–86.

Article14. Karakaya S, Sengun A, Ozer F. Evaluation of internal adaptation in ceramic and composite resin inlays by silicon replica technique. J Oral Rehabil. 2005; 32:448–53.

Article15. Shin Y, Park S, Park JW, Kim KM, Park YB, Roh BD. Evaluation of the marginal and internal discrepancies of CAD-CAM endocrowns with different cavity depths: an in vitro study. J Prosthet Dent. 2017; 117:109–15.16. Boitelle P, Mawussi B, Tapie L, Fromentin O. A systematic review of CAD/CAM fit restoration evaluations. J Oral Rehabil. 2014; 41:853–74.17. Stappert CF, Chitmongkolsuk S, Silva NR, Att W, Strub JR. Effect of mouth-motion fatigue and thermal cycling on the marginal accuracy of partial coverage restorations made of various dental materials. Dent Mater. 2008; 24:1248–57.

Article18. Park SH, Yoo YJ, Shin YJ, Cho BH, Baek SH. Marginal and internal fit of nano-composite CAD/CAM restorations. Restor Dent Endod. 2016; 41:37–43.

Article19. Goujat A, Abouelleil H, Colon P, Jeannin C, Pradelle N, Seux D, et al. Marginal and internal fit of CAD-CAM inlay/onlay restorations: a systematic review of in vitro studies. J Prosthet Dent. 2019; 121:590–7.20. Rippe MP, Monaco C, Volpe L, Bottino MA, Scotti R, Valandro LF. Different methods for inlay production: effect on internal and marginal adaptation, adjustment time, and contact point. Oper Dent. 2017; 42:436–44.

Article21. Seo D, Yi Y, Roh B. The effect of preparation designs on the marginal and internal gaps in Cerec3 partial ceramic crowns. J Dent. 2009; 37:374–82.

Article22. Tsitrou EA, Northeast SE, van Noort R. Evaluation of the marginal fit of three margin designs of resin composite crowns using CAD/CAM. J Dent. 2007; 35:68–73.

Article23. DeLong R, Pintado MR, Ko CC, Hodges JS, Douglas WH. Factors influencing optical 3D scanning of vinyl polysiloxane impression materials. J Prosthodont. 2001; 10:78–85.

Article24. El Zohairy AA, De Gee AJ, Mohsen MM, Feilzer AJ. Microtensile bond strength testing of luting cements to prefabricated CAD/CAM ceramic and composite blocks. Dent Mater. 2003; 19:575–83.

Article25. Zarrati S, Mahboub F. Marginal adaptation of indirect composite, glass-ceramic inlays and direct composite: an in vitro evaluation. J Dent (Tehran). 2010; 7:77–83.26. Sener-Yamaner ID, Sertgöz A, Toz-Akalın T, Özcan M. Effect of material and fabrication technique on marginal fit and fracture resistance of adhesively luted inlays made of CAD/CAM ceramics and hybrid materials. J Adhes Sci Technol. 2017; 31:55–70.

Article27. Groten M, Axmann D, Pröbster L, Weber H. Determination of the minimum number of marginal gap measurements required for practical in-vitro testing. J Prosthet Dent. 2000; 83:40–9.

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- Correction to “Marginal fit of three different nanocomposite inlays fabricated with computer-aided design/computer-aided manufacturing (CAD/CAM) technology: a comparative study”

- CAD/CAM fabricated complete denture using 3D face scan: A case report

- Fabrication of computer-aided design/computer-aided manufacturing complete denture and conventional complete denture: case report

- RPD framework fabrication using computer-aided design (CAD) and rapid prototyping

- How adjustment could affect internal and marginal adaptation of CAD/CAM crowns made with different materials