J Korean Foot Ankle Soc.

2023 Sep;27(3):112-116. 10.14193/jkfas.2023.27.3.112.

Corrective Surgery Using Virtual Surgical Simulation and a Three-Dimensional Printed Osteotomy Guide: A Case Report

- Affiliations

-

- 1Department of Orthopedic Surgery, Korea University Ansan Hospital, Ansan, Korea

- KMID: 2545991

- DOI: http://doi.org/10.14193/jkfas.2023.27.3.112

Abstract

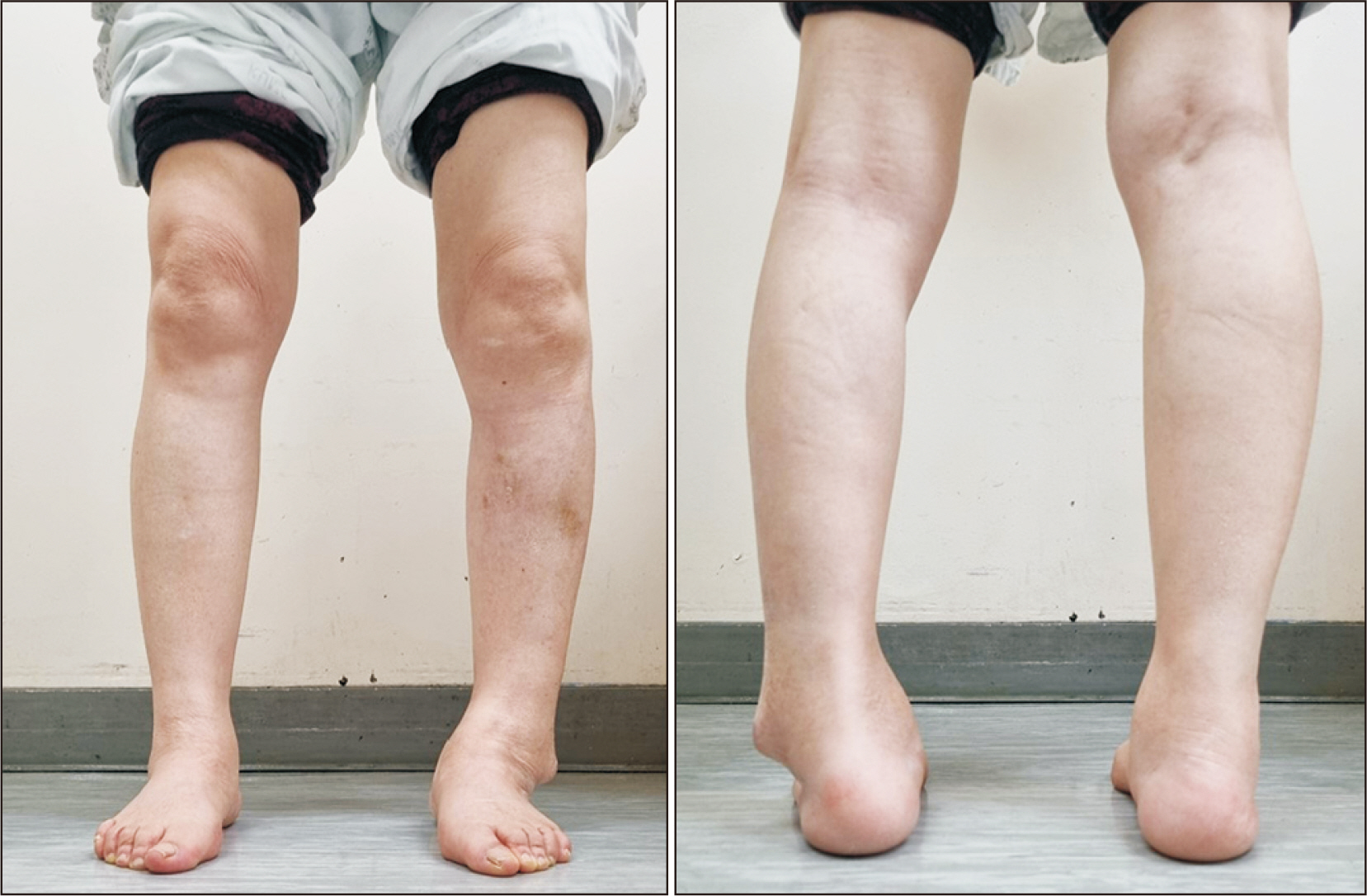

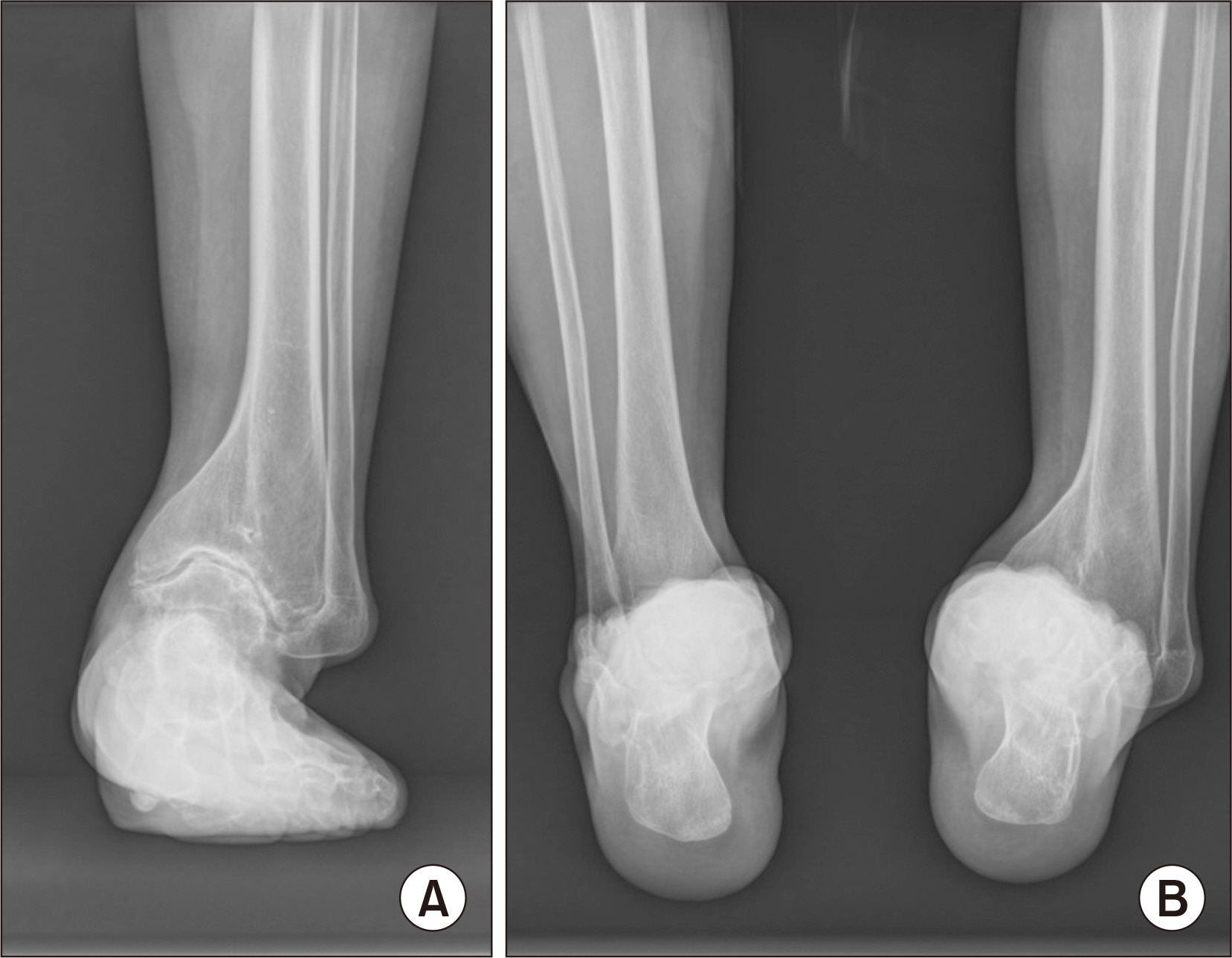

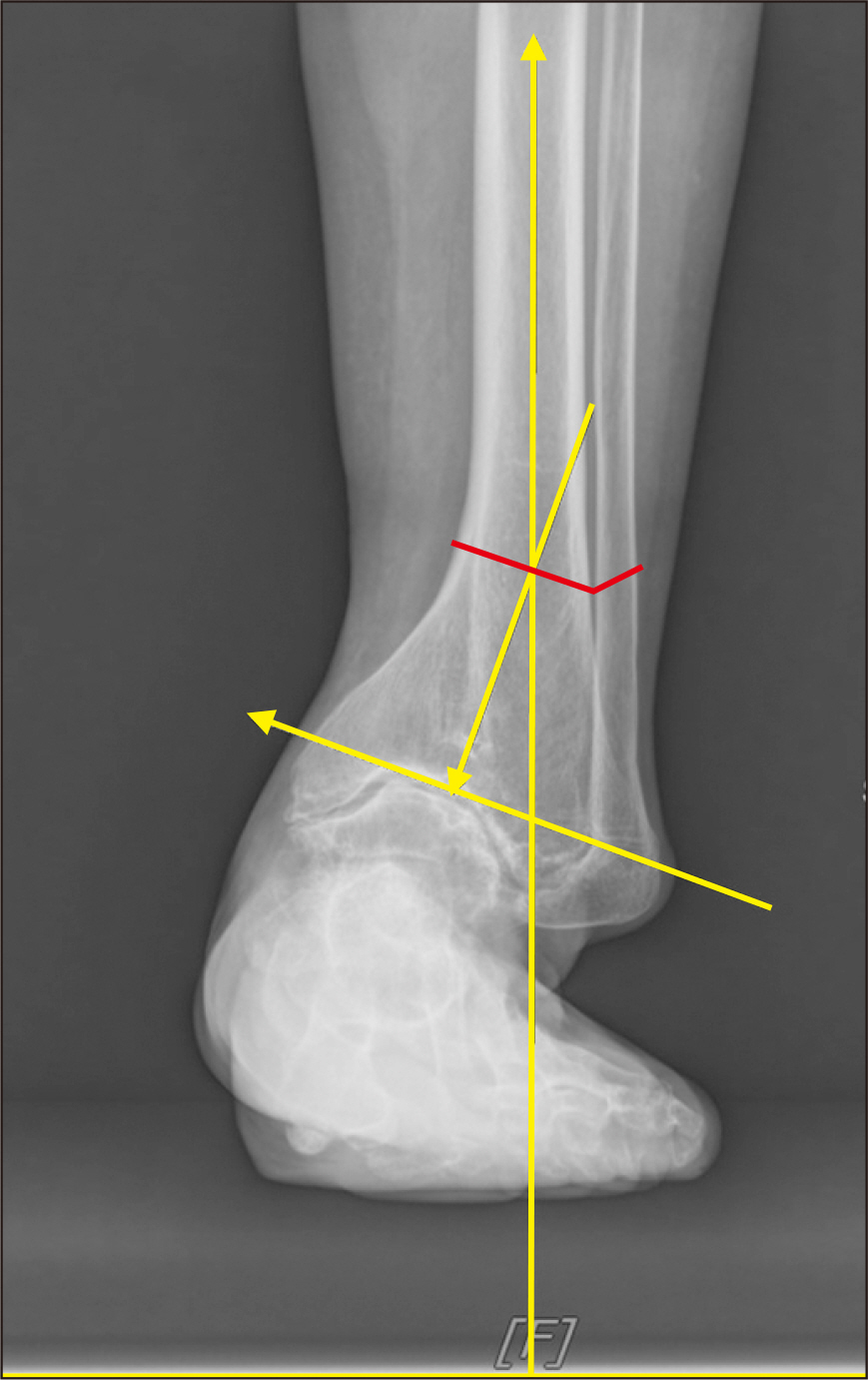

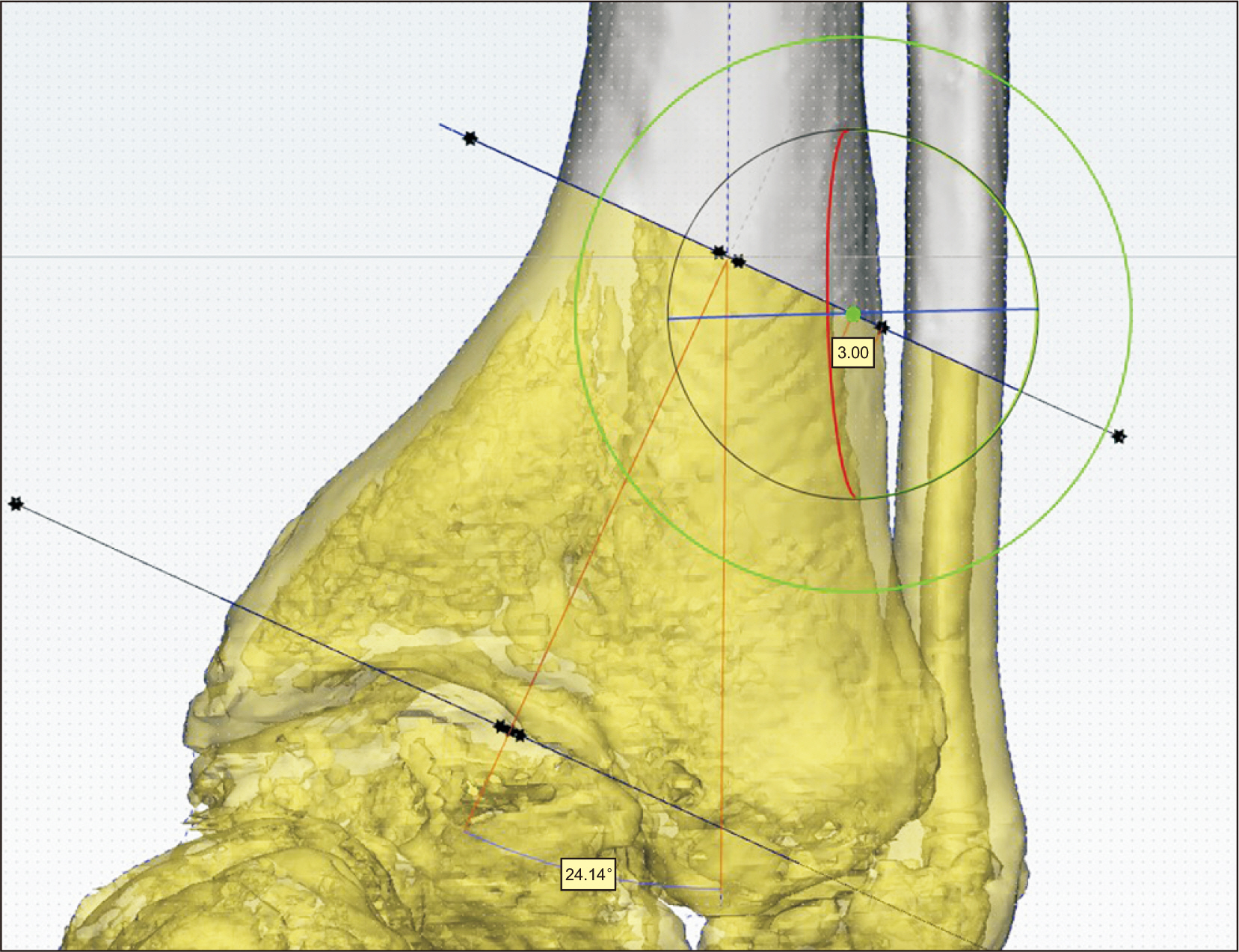

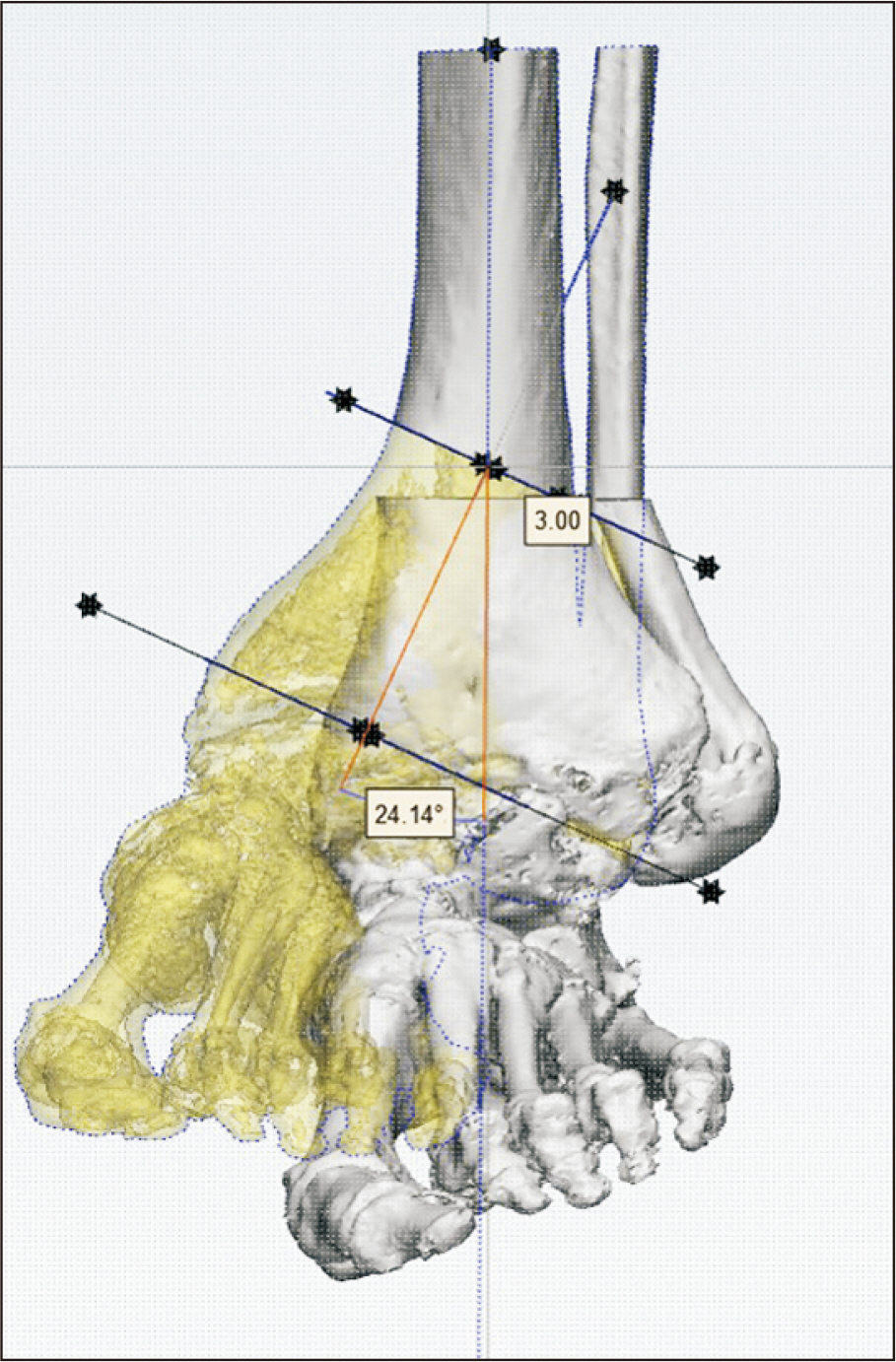

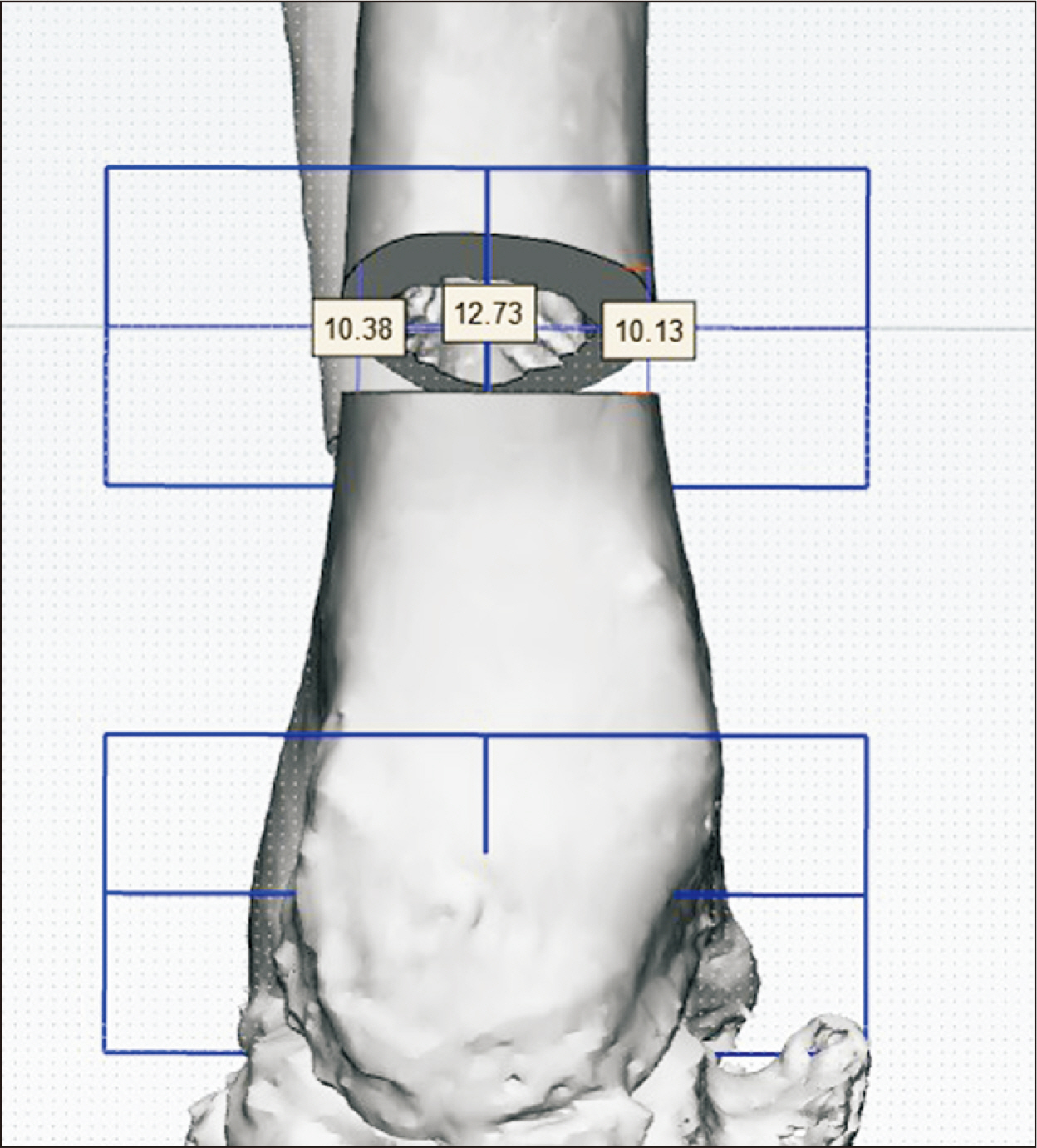

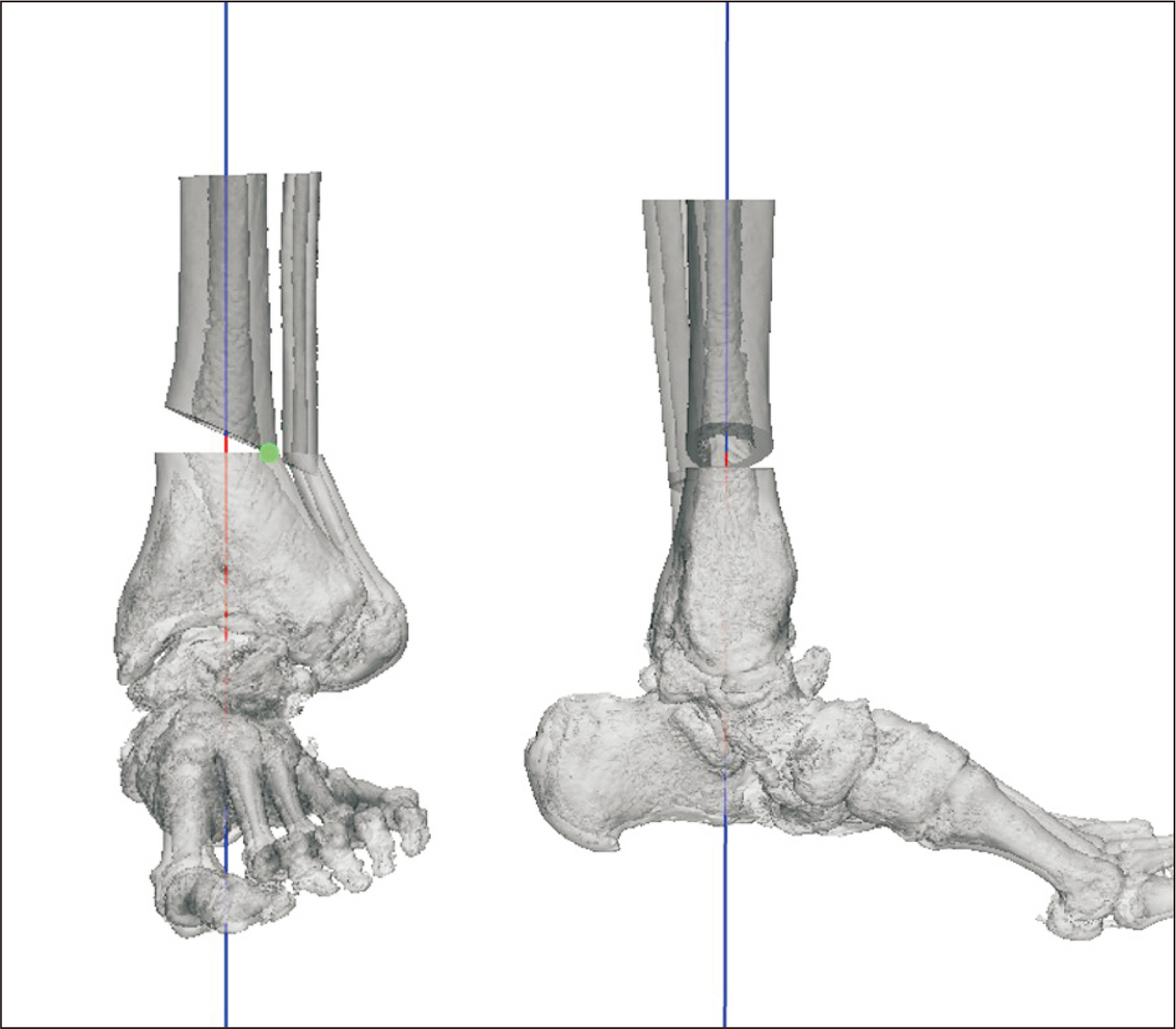

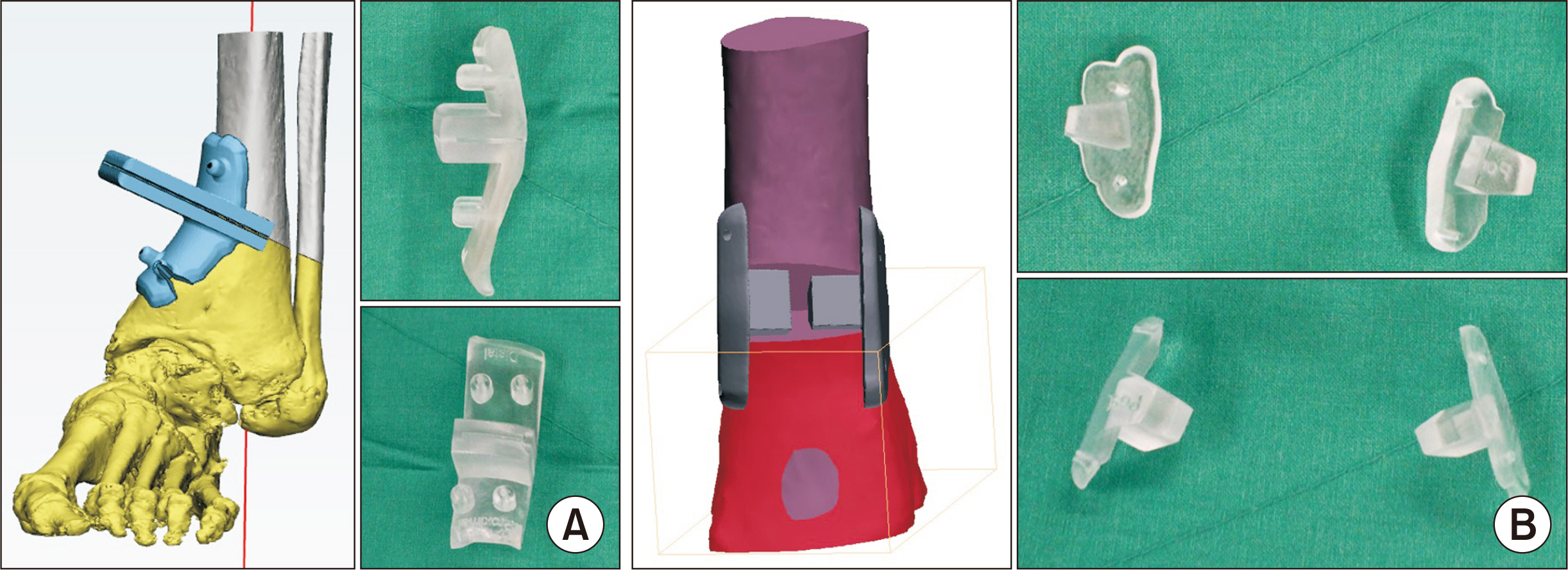

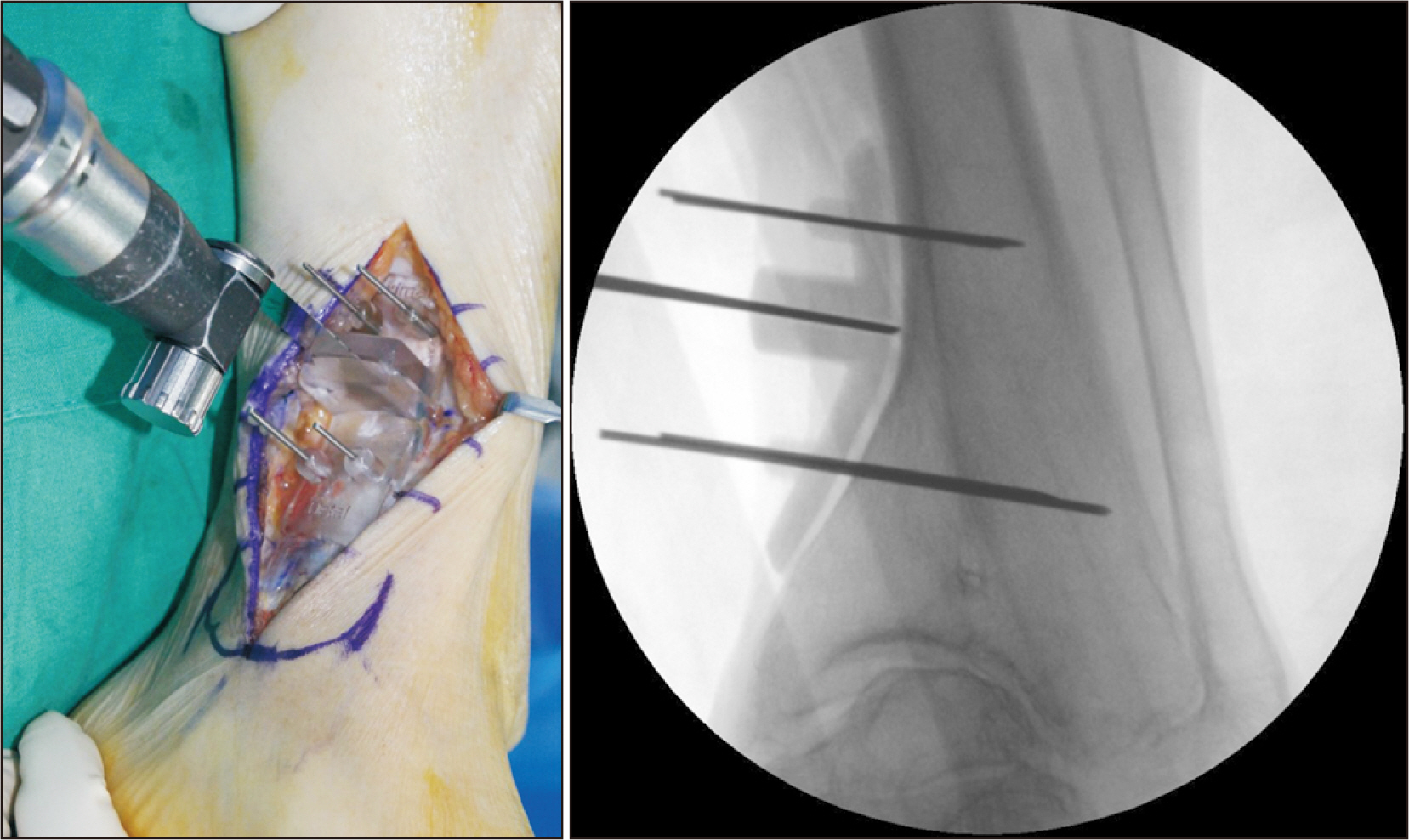

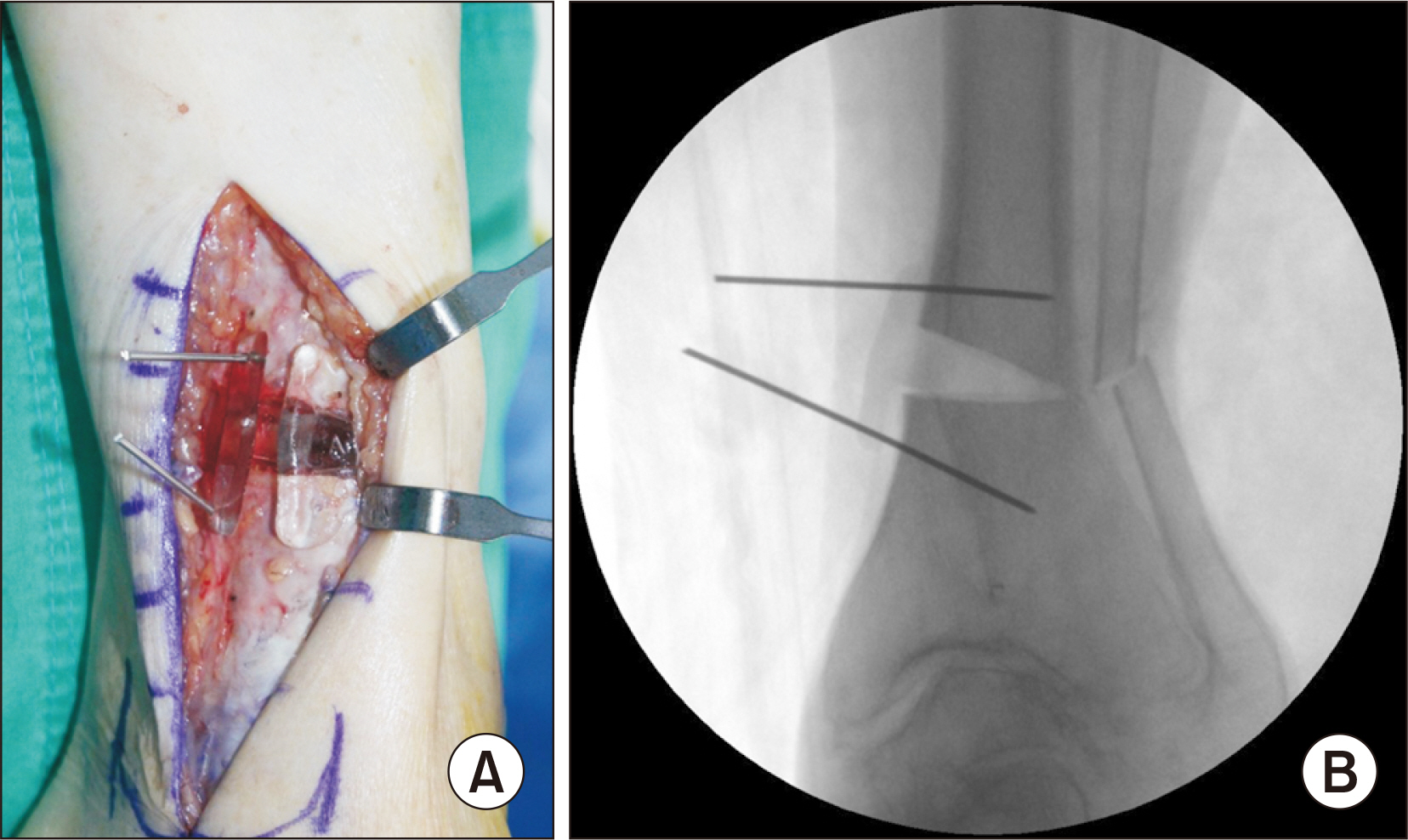

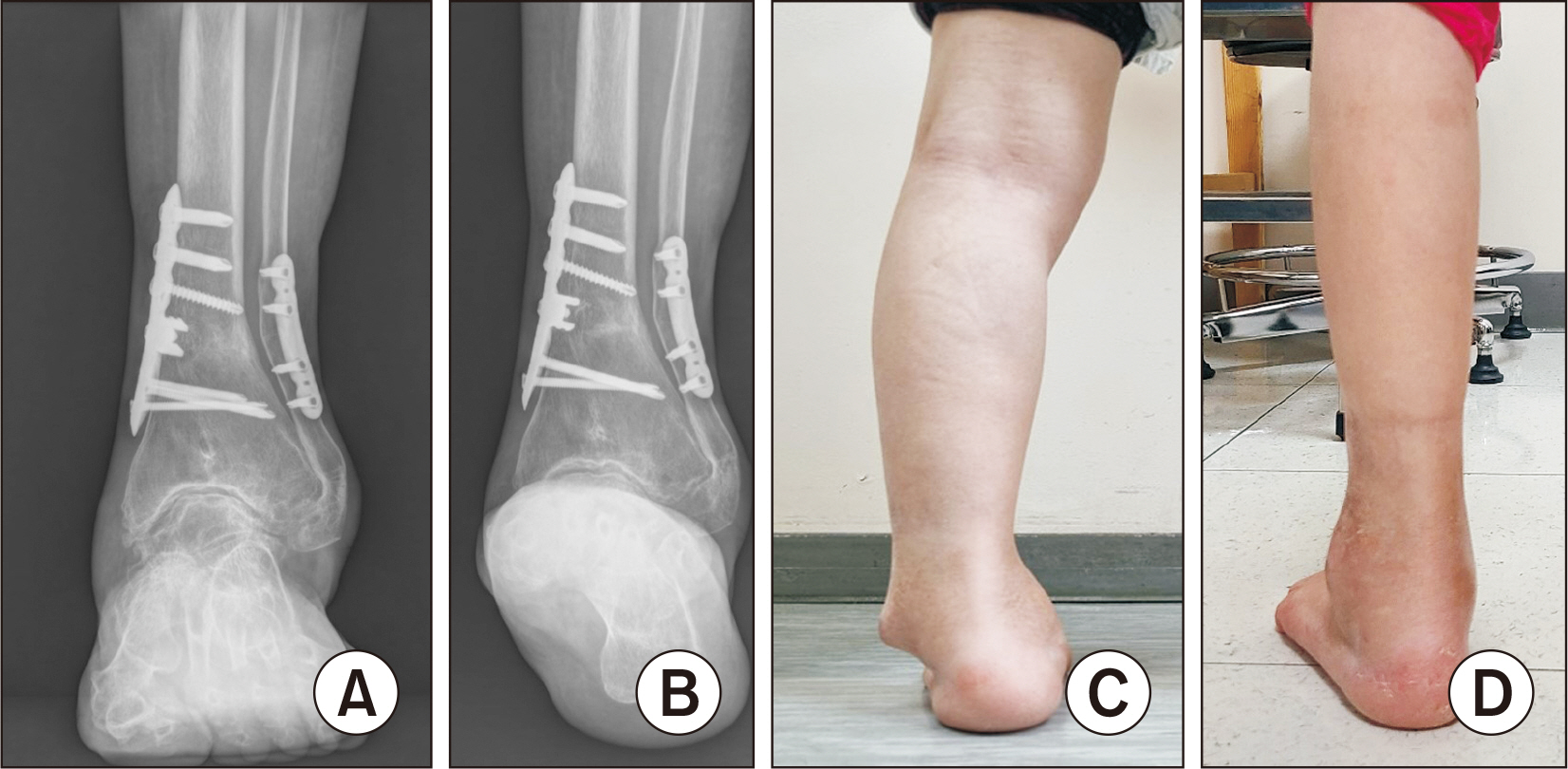

- A 74-year-old female patient, who underwent surgery for a left distal tibiofibular fracture 40 years earlier, visited the hospital with an ankle varus deformity due to malunion. The patient complained of discomfort while walking due to the ankle and hindfoot varus deformity but did not complain of ankle pain. Therefore, correction using supramalleolar osteotomy was planned, and through virtual surgical simulation, it was predicted that a correction angle of 24° and an osteotomy gap open of 12 mm would be necessary. An osteotomy guide and an osteotomy gap block were made using three-dimensional (3D) printing to perform the osteotomy and correct the deformity according to the predicted goal. One year after surgery, it was observed that the ankle varus was corrected according to the surgical simulation, and the patient was able to walk comfortably. Thus, for correction of deformity, virtual surgical simulation and a 3D-printed osteotomy guide can be used to predict the target value for correction. This is useful for increasing the accuracy of correction of the deformity.

Figure

Reference

-

1. Bastawrous S, Wu L, Strzelecki B, Levin DB, Li JS, Coburn J, et al. 2021; Establishing quality and safety in hospital-based 3D printing programs: patient-first approach. Radiographics. 41:1208–29. doi: 10.1148/rg.2021200175. DOI: 10.1148/rg.2021200175. PMID: 34197247.

Article2. Pabst A, Goetze E, Thiem DGE, Bartella AK, Seifert L, Beiglboeck FM, et al. 2022; 3D printing in oral and maxillofacial surgery: a nationwide survey among university and non-university hospitals and private practices in Germany. Clin Oral Investig. 26:911–9. doi: 10.1007/s00784-021-04073-6. DOI: 10.1007/s00784-021-04073-6. PMID: 34278522.

Article3. Pugliese L, Marconi S, Negrello E, Mauri V, Peri A, Gallo V, et al. 2018; The clinical use of 3D printing in surgery. Updates Surg. 70:381–8. doi: 10.1007/s13304-018-0586-5. DOI: 10.1007/s13304-018-0586-5. PMID: 30167991.

Article

- Full Text Links

- Actions

-

Cited

- CITED

-

- Close

- Share

- Similar articles

-

- Genioplasty using a simple CAD/CAM (computer-aided design and computer-aided manufacturing) surgical guide

- Unilateral intraoral vertical ramus osteotomy based on preoperative three-dimensional simulation surgery in a patient with facial asymmetry

- Computer Simulation Surgery for Mandibular Reconstruction Using a Fibular Osteotomy Guide

- Surgery-first approach using a three-dimensional virtual setup and surgical simulation for skeletal Class III correction

- Surgical Stent Fabrication and Clinical Application for Orthognathic Surgery Using Cone-Beam CT